-

Product

- Pellet Mill

- Wood Pellet Mill

- Vertical Pellet Mill

- Feed Pellet Line

- Peletizadora de Pienso

- Extrusor seco

- Movable Pellet Plant

- Shredder

- Sawdust Producer

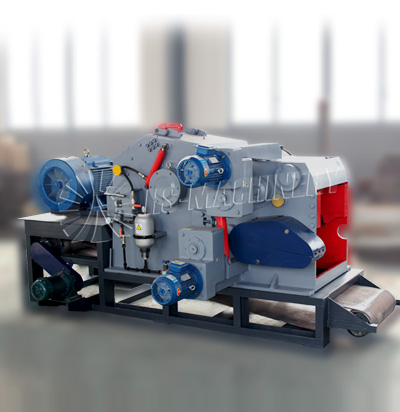

- Drum Chipper

- Wood Chips Hammer Mill

- Shearing Milling Machine

- Wood Blocks Hammer Mill

- Double-shaft Rollers Shredder

- Rotary-disc Type Shredder

-

Solution

-

Case

-

Service

-

Faq

-

About

-

Contact